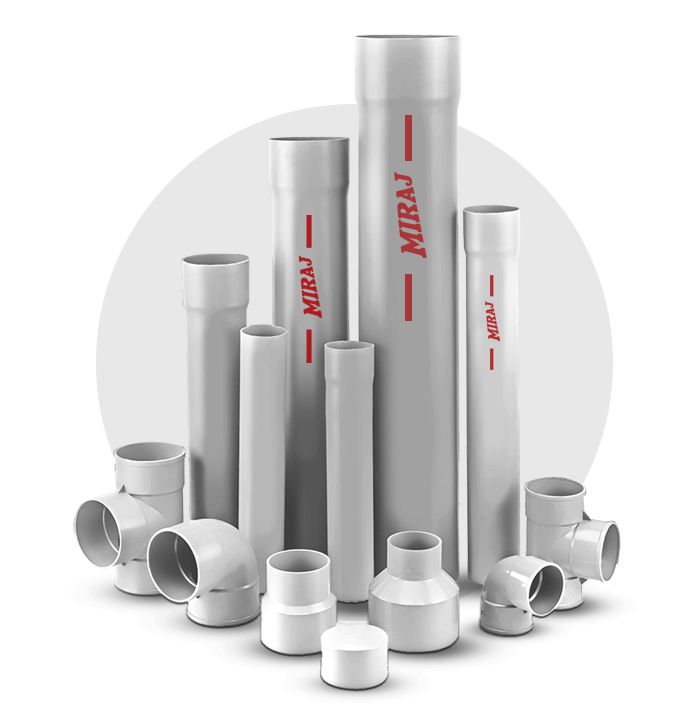

uPVC COLUMN PIPES

Miraj uPVC Column pipes are manufactured within the world class Quality Management System as per ISO 9001:2008. Miraj UPVC Column Pipes are used for submersible boring applications.

Product Range & Applications

Product Range

- Range : 1” to 4”

- Type : 10 kg/cm2 , 12.5 kg/cm2, 15 kg/cm2, Medium, Standard & Heavy

- Bell & coupler type

Application

- uPVC Column pipes are used for submersible boring applications. It's capable of handling both internal hydrostatic pressure as well as high tensile load caused by the pump weight & column water pressure and weight. Adjustable according to the depth of water level. Suitable for upto 300 mtr depth. कॉलम पाइप सबमर्सिबल बोरिंग अनुप्रयोगों के लिए उपयोग किया जाता है। पंप के वजन और पानी के दबाव और वजन के कारण उत्पन आंतरिक हाइड्रोस्टैटिक दबाव और साथ ही उच्च तन्यता लोड यह दोनों को संभालने में सक्षम है। जल स्तर की गहराई के अनुसार एडजस्टेबल। 300 मीटर गहराई तक उपयुक्त है।

Advantages

- High tensile strength and high pressure rating./उच्च तन्यता ताकत और उच्च दबाव रेटिंग।

- Excellent pull out strength./ उत्कृष्ट बाहर खींचने की ताकत।

- Pipe & Coupler having square thread for excellent mechanical properties and easy in assembly and disassembly./पाइप और कप्लर में उत्कृष्ट यांत्रिक गुणों के लिए इसमें चौकोर धागा है, और यह लगाने और हटाने में सुविधाजनक है

- One side pipe & coupler having special thread locking for preventing thread slippage during assembly and disassembly with load of submersible pump and pipes./एक तरफ पाइप और कप्लर में उत्कृष्ट यांत्रिक गुणों के लिए इसमें चौकोर धागा है जो सुब्मर्सिबल पंप और पाइप को जोड़ते और हटाते समय फिसलन को रोकता है |

- High tensile strength of pipe coupler locking so lock safety is 100%./पाइप कप्लर की उच्च तन्यता शमता के कारण लॉकिंग सुरक्षा 100 % है |

- Low friction losses due to excellent smooth internal surface./ उत्कृष्ट चिकनी आंतरिक सतह के कारण कम घर्षण होता है |

- Resistant to chemical reaction, bacterial growth, corrosion, rusting etc./रासायनिक प्रतिक्रिया, जीवाणु वृद्धि, संक्षारण, जंग आदि को रोकता है|

Why Miraj Pipes ?

Why Miraj Pipes ?

High tensile strength and high pressure rating

Miraj pipes and fittings are engineered for exceptional performance with a combination of high tensile strength and an impressive pressure rating. This robust design ensures reliability under demanding conditions, making Miraj the preferred choice for applications requiring both strength and resilience in plumbing systems.

Resistant to chemical reaction, bacterial growth

Miraj pipes and fittings offer comprehensive protection against chemical reactions, bacterial growth, corrosion, and rusting. Our advanced materials ensure a resilient barrier, making Miraj the ideal choice for safeguarding plumbing systems from various environmental challenges, ensuring longevity and reliability in diverse applications.